Full rework station for all applications from XS to XXL component sizes

The WXsmart is a centralized control unit acting as the brain of the workbench – by controlling multiple devices at the same time

New intelligent tips and tools provide smart features thanks to the integrated chip in every soldering iron

Smart intelligent Tips & Tools

Lightning Fast Performance

Two irons cover all applications

Backwards compatibility

to all existing Weller WX soldering, desoldering and hot air irons as well as solder bath and preheating plate

Flexibility

Easily upgrade your soldering station to a full rework station to avoid high investment costs and to save space on the workbench

Benchtop control

the WXsmart is a centralized control unit acting as the brain of the workbench by controlling multiple devices at the same time which saves time, space and money

WXP80, T0052920999N

80 W 24 V - SOLDERING IRON WITH SILVER LINE HEATING TECHNOLOGY

For medium components with high energy demand.

WXP90, T0052922599N

90 W 24 V - HYBRID SOLDERING IRON WITH POWER RESPONSE HEATING TECHNOLOGY

For small and medium components with high energy demand.

WXP120, T0052920299N

120 W 24 V - SOLDERING IRON WITH POWER RESPONSE HEATING TECHNOLOGY

For small and large components (High Mass) with high energy demand.

WXP200, T0052920699N

200 W 24 V - SOLDERING IRON WITH POWER RESPONSE HEATING TECHNOLOGY

For very large components (Shielding) with high/ medium energy demand.

WXPP, T0052922699

WXPP MS (MIL SPEC) T0052923299

40 W, 12 V - PICO SOLDERING IRON WITH ACTIVE HEATING TECHNOLOGY

For very small and small components and miniature works under a microscope with high energy demand. MS version according to Military Standard.

WXMP T0052920499N

WXMP MS (MIL SPEC) T0052921799N

40 W, 12 V - MICRO SOLDERING IRON WITH ACTIVE HEATING TECHNOLOGY.40 W, 12 V

For medium to large components with high energy demand. MS version according to Military Standard

WXDP120, T0051320299N

120 W 24 V - DESOLDERING IRON FOR HORIZONTAL USE WITH DESOLDERING NOZZLE

WXDV120, T0051320599N

120 W 24 V - DESOLDERING IRON FOR VERTICAL USE WITH DESOLDERING NOZZLE

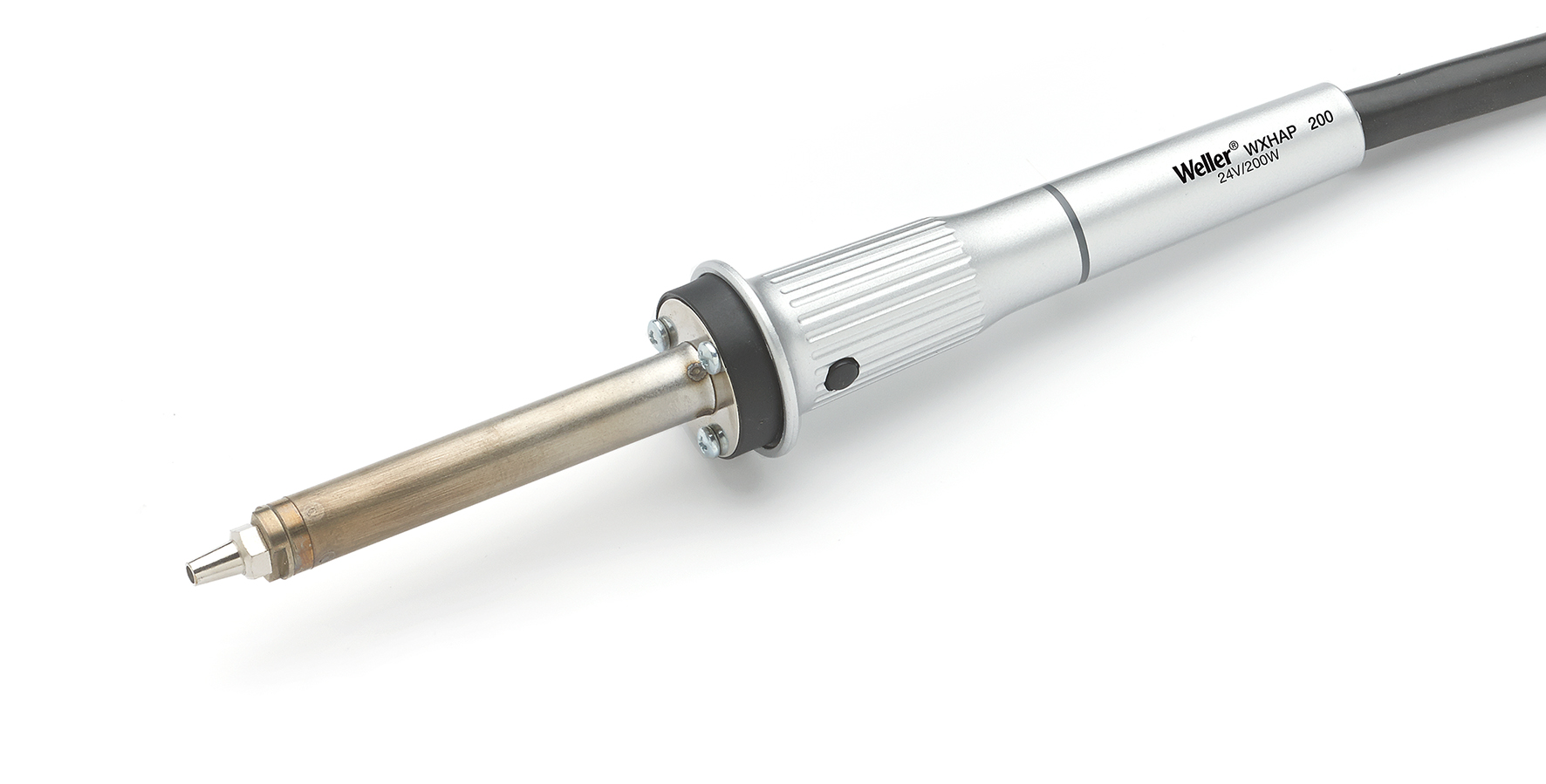

WXHAP200 , T0052712099N

200 W, 24 V - HOT AIR IRON WITH HOT AIR NOZZLE

WCU, T0053452699 (EMEA), T0053452299 (US)

TEMPERATURE MEASURING DEVICE AND AUTO CALIBRATION UNIT

WXHP120, T0052702999N

120 W PREHEATING PLATE

WHP1000, T0053364899N (EMEA), WHP1000N (US)

1000 W PREHEATING PLATE

WHP3000, T0053338699N (EMEA), WHP3000N (US)

600 W PREHEATING PLATE

WHP3000, T0053364699N (EMEA)

1200 W PREHEATING PLATE

WXSB200, T0052704399N

200 W SOLDER BATH

WXSF120, T0051391199

FLOWIN SMART SOLDER FEEDER SYSTEM

ZERO SMOG 4V, T0053662699N (EMEA), T0053662299N (US)

VOLUME EXTRACTION UNIT FOR 4 WORKPLACES - ESD-SAFE

ZERO SMOG 6V, T0053666699N (EMEA), T0053666299N (US)

VOLUME EXTRACTION UNIT FOR 6 WORKPLACES - ESD-SAFE

ZERO SMOG 20T, T0053670699N (EMEA)

TIP EXTRACTION UNIT FOR 20 WORKPLACES - ESD-SAFE

One investment for one platform to cover all soldering applications.

Save time with an organized workplace

Only one station on the workbench for all soldering and desoldering applications saves space.

Sr. Director, Marketing Operations & Communications

The WXsmart is an all-in-one station (Soldering / Desoldering / Hot Air) that saves space, time and costs, and supports Smart Soldering 4.0 with intelligent tips and tools. The station will work as brain of the workbench giving full control for fume extraction units, pre-heating plates and calibration units.

The new smart Tips of Weller are offering multiple new features thanks to the integrated chip in every soldering tip:

• Automatic Tip Identification

• Tip Lock functionality for full process control

• Every tip has a unique individual serial number for full traceability

• All smart tips are calibrated ex works

• Easy Auto-Calibration - with Tip-Offset for best precision

• Full Traceability on calibration history of every single tip

• Patented tip & grip design

• Fast tool-less tip change

Weller will offer the widest range of smart soldering tips worldwide for Nano, Micro & Heavy-Duty soldering applications.

Weller will launch two new smart soldering irons for smart Pico, Micro and Ultra soldering tips.

The new irons will come with an RGB ring light, which is able to show a clear visual channel

identification. The light will function as visual process control for example:

indicate if the iron is off, in standby, in the heat-up process or in operating modus.

Thanks to the new feature of automatic tip identification, Weller developed a

2-in-1 WXMPS MS Soldering Iron = which will allow to use smart Pico and Micro Tips on the same iron.

Features

• Active Tip (Cartridge)-System allows exchange of soldering tip despite a hot soldering iron

• Parameter memory such as standby temperatures, automatic switch-off time

• Motion activated

• Patented Tip & Grip Design

• Extremely short heating time

• Excellent heat transfer and sensors

• Military Standard (MIL-SPEC)

Production within the electronics, medical technology and aerospace industries is moving faster as

components become smaller, more sensitive, complex and more powerful. The soldering industry is not

different. With the Weller Smart tips you meet these increasing demands.

The Weller Smart MS (military standard) soldering tips are fully compliant with IPC industry standards

(IPC - TM-650 2.5.33 Measurement of Electrical Overstress from Soldering Hand Tools) and are also

MIL-SPEC compliant.

The RT-Smart Lines provide maximum protection to the printed circuit board and the component you're

soldering. With the MS tips you achieve the best results and keep your operation costs as low as

possible.

With the WXair you can extend at any time your WXsmart soldering station

to a de-soldering and hot air station (Full Rework Station). The WXair is a self-contained module so it

is immediately ready to work.

The WXair is compatible with the new WXsmart and also with our existing portfolio (WX 1, WX 2, WXD 2,

WXA 2).

The module is designed to be stackable so you can place the WXsmart easily on top of the WXair saving

space on your workbench.

It is the first 2-in-1 Module in the soldering market combining de-soldering and hot air functions in

one unit. This is saving space and money.

It is possible to connect all existing WX Tools to the new WXsmart station.

The WXsmart soldering station is equipped with various possibilities for potential equalization:

a) Hard ground without plug (original delivery)

b) Potential equalization with plug - equalization line

on center contact

c) Potential free - with plug

d) Soft ground - with plug and resistor soldered in: Grounding according to selected resistor